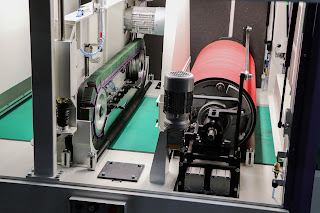

When it

comes to achieving flawlessly rounded edges for your laser parts and small

components, the DM1100 C and DM1600 C edge rounding machines are your ultimate

solution. These machines are meticulously designed with user-friendliness and

efficiency in mind, ensuring a hassle-free process that consistently delivers

impeccable results.

A Seamless Process for Perfection

Operating the DM1100 C and DM1600 C is a breeze, and the dimensions of these machines play a crucial role in their versatility. The DM1100 C boasts a maximum width capacity of 1100mm, while the DM1600 C can handle widths of up to 1600mm.

These dimensions are vital for two key reasons:

Handling

Larger Parts: With the DM1600 C's impressive 1600mm width capacity, you can

effortlessly feed and process more substantial parts. This capability opens up

new possibilities for working with larger components, expanding the range of

applications for these machines.

Efficient

Batch Processing: The generous width capacity also allows for the simultaneous

processing of multiple small parts on the conveyor belt. This means you can

maximize efficiency by deburring and rounding edges on numerous small

components in a single run. Whether you're handling large or small parts, these

machines adapt to your needs with ease.

As your

part navigates its way through the conveyor belt, it encounters two sets of abrasive

blocks working in opposing directions. This ensures that whether you're working

with smaller laser parts or larger components, these machines have the capacity

to meet your needs. As your part emerges on the other side, you'll be greeted

with rounded edges, devoid of any rough surfaces or burrs, both on

the inner and outer contours. This yields a sleek and professional finish that

leaves a lasting impression.

Key Benefits of Our Edge Rounding Machines

Reduced

Setup Time

Contrary to

common belief, programmable controllers don't always simplify deburring

machines. The non-EVO versions of our machines prioritize speed and simplicity. Thanks to direct input

through hand wheels and straightforward on/off buttons, setup transitions from

one job to the next in seconds. You can adjust material thickness, feed rate,

and grinding pressure on the fly, all without interrupting the machine's

operation.

Accelerated

Operator Training

Training

operators for these machines is a breeze, as minimal programming is required.

As Steve Anderson, President of G.A. Systems Inc., attests, "Anybody can

run it. You just set the height and let it do its work."

Reduced

Component Failures

Complexity

often leads to downtime. We've dedicated ourselves to simplicity, resulting in

superior uptime for our C Equipment and a lower cost of ownership. Our machines

are built for reliability and longevity.

Minimized Operator Errors

Easy-to-use

machines lead to fewer operator errors. Operators can visually and intuitively

monitor their inputs, preventing costly mistakes and ensuring a continuous flow

of parts through the machine. This boosts operator confidence and productivity.

Your Partner in Deburring and Edge Rounding

Our edge

rounding machines are the go-to choice for achieving top-tier deburring and quality edges on metal parts. Whether you're working with

laser, punching or shear cut parts, small components, or larger metal pieces, our machines

rise to the challenge. Bid farewell to manual edge rounding and embrace a

more efficient process with our metal deburring machines.

If you have any questions about those finishing machines or need to make some tests please contact us through marketing@nsmaquinas.pt or on our contact page: https://nsmaquinas.com/contacts/.